ON-SITE TOOL ROOM AND MAINTENANCE SUPPORT

FULL SERVICE On-Site Toolrooms

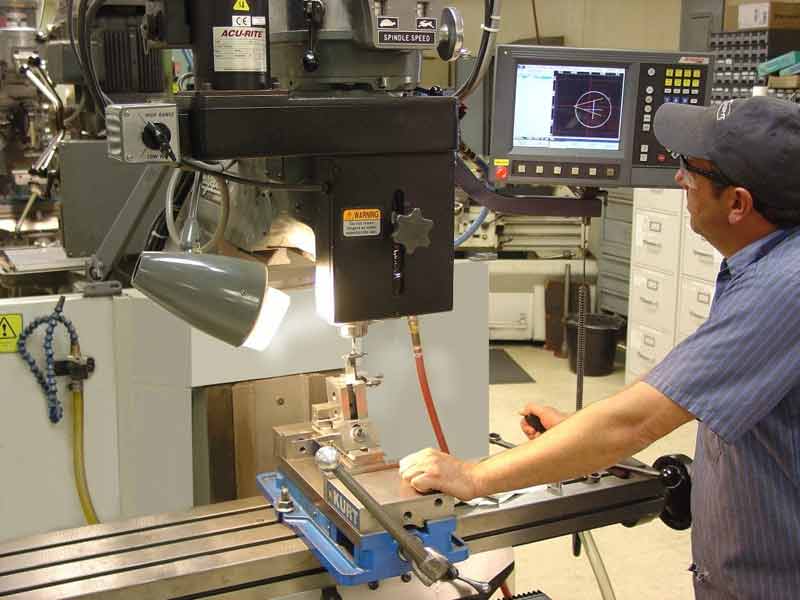

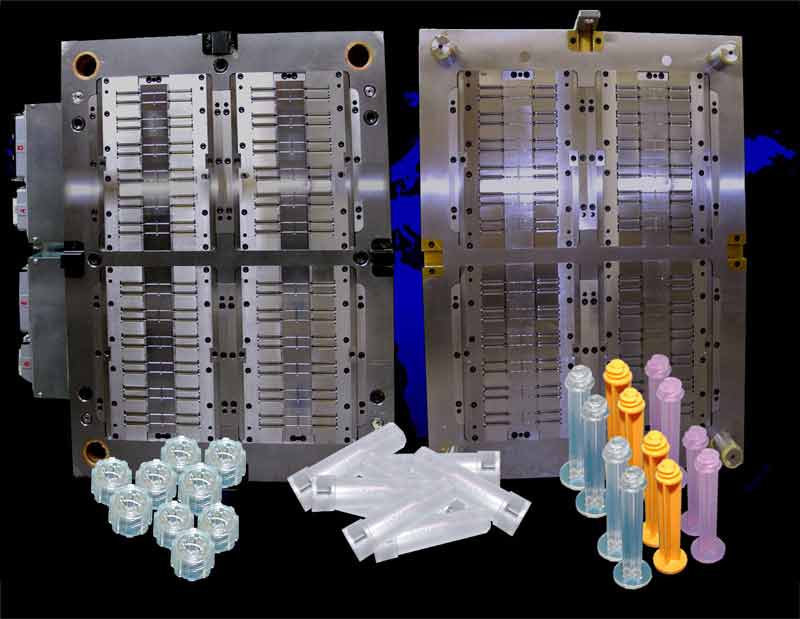

Majors provides highly skilled in-house toolmakers and a fully stocked tool room to ensure accurate and timely repairs and maintenance on all your molds. We also do "Hot Runner" maintenance & cleaning. Accurate and complete recordsand history files are maintained on all molds within the Major's facilities. Our toolmakers specialize in critical tolerance molds. All molds are maintained, cleaned and serviced with thought to the quality parts your customers demand.

Our personnel are also skilled in manufacturing the specialty fixtures and robotic end-of-arm tooling that you require for your unique parts throughout the molding and assembly processes

Mold Support, Documentation and Maintenance

Majors provides on-going maintenance and service throughout the life of the mold. Our design team, engineering team and toolmakers will work closely with you on engineering changes or issues that may occur. We maintain detailed and accurate mold documentation records for all our customers’ molds, including scheduled periodic tool inspections, real-time cycle counts, and scheduled cleaning.

We also provide experienced equipment maintenance personnel and technicians in all our facilities to ensure equipment uptime so your parts are manufactured and delivered on time.

- Highly Skilled In-House Toolmakers

- Mold Modifications & Repair

- Scheduled Periodic Tool Inspections and Cleaning

- Monitor and Documenting Real-Time Cycle counts

- Hot Runner Maintenance, Cleaning & Repair

- Cavity & Core Welding

- Design and Manufacture of Custom Fixtures and End-of-Arm Tooling

- Complete and Detailed Mold History Files Maintained on all Customer Molds

- In House Equipment Maintenance